To cater to the needs of various companies regarding their storage requirements of various goods and food items, DIGNUS-INFRA offers the most modern, state-of-the-art, full service temperature controlled warehouses/Cold Rooms which are constructed using pre-fabricated PUF/PIR panels designed specifically for such applications, and manufactured to international standards of quality and reliability at state-of-the-art facilities. These panels are packed with advanced high-density foamed-in-place PUF/PIR insulation to ensure high-efficiency insulation, and metal-finished (a choice of aluminium, pre-painted steel, stainless steel, galvanised steel or Galvalume).

DIGNUS-INFRA Panel System provides a very good tight chamber for storage by proper sealing of all jointing between the panels. This ensures a proper maintenance of the oxygen, carbon dioxide content, humidity and temperature inside the CA room. DIGNUS-INFRA Panels are capable of bearing over pressures upto 30kg/m2.

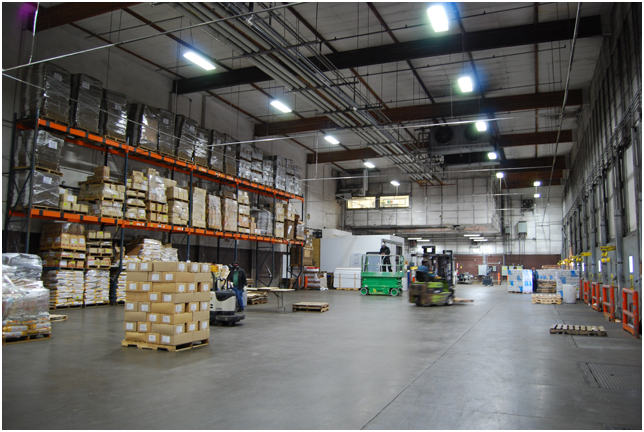

DIGNUS-INFRA offers customized turnkey solutions for cold storages and refrigerated warehouses, to sustain the special low temperatures required to preserve a range of products including (among others):

- Fresh fruits & vegetables

- Meat, fish, poultry

- Dairy products

- Floriculture

- Industrial raw materials / finished goods

- Food products for retailing

- Pharmaceutical products

Perishable items can be stored in such rooms for a longer time period without any spoilage. These rooms are built on engineering principles, so as to provide maximum insulation. Modular in nature, these tongue-and-groove panels in a range of thicknesses and dimensions are designed to interlock with ease at site with the additional jointing system by Camlock to form cold rooms of any size and for any application. Each part of the cold room – walls, ceiling, floor, doors and even T-walls and corners – have special panels designed for the purpose to ensure perfect fit.

These modular cold rooms are not just easily assembled at site. They are easily disassembled too and moved when required, or even enlarged or split into multiple rooms as later needs may demand.

As of today, we have a separate division to work on Post Harvest Management of Horticultural includes Design Solutions, Supply, and Execution of various Cold Chain Projects including:

- Pre-cooling System, with mobile pre-cooling where needed.

- Refrigerated Infrastructure required at Rural Markets – various State Agriculture Marketing Board assignments.

- Transit Cold Storage / Storage Facilities.

- Refrigerated Transport System.

- Refrigerated Railway Wagons.

- Refrigerated Cargo Containers.

- Cold Storages / CA Storages / ULO Storages.

- Refrigerated Retail Outlets.